There are three installing methods available for a kitchen sink: undermount, top mount, and flush mount.

In this article, we will talk about the difference between the two most often used installing method for a granite composite sink

-undermount and top-mount.

Let’s get right to it.

What’s The Difference Between Top-mount And Undermount Sinks?

The Standard Design Difference

Undermount design offers a lot more space.

The undermount sink is more integrated and concealed; that is too under the same sink size. The undermount sink gets an advantage over the top-mount as the panel’s installation, console control, and faucet are eliminated during the process.

At the same time, the top-mount sink gives a more elegant look. The sinks’ rims create a remarkable design. The quartz sink’s sturdy edge gives it a more robust finish than the undermount sink.

There can also be more variety in terms of design. One way to do this is to significantly decrease the R radius’s width on the sink, giving the sink a more sleek and elegant look.

The Process of Installation

Suppose you have any prior experience in renovation and makeovers. In that case, you will indeed have an idea that the installation of an undermount sink is, comparatively, more complicated than that of the top-mount sink.

First of all, the countertop’s size must align with the sink’s inner diameter (as shown in the figure below), with a fundamental deviation. Its size and dimension’s mandatory requirements are as follows.

Otherwise

Size should not exceed the limit of ±2mm. R radius must match the sink itself. If we can meet these conditions, the process of installation will not take place.

While on the contrary, the top-mount sinks do not have such concerns. The countertop size’s size is minus 20mm of the top-mount sink’s size in both length and width. Considering both sinks’ protocols, the craftsman worker will most likely recommend getting a top-mounting sink over the countertop.

Universal Adaptation Difference

The fact that favors the top-mount sink is that it has its console control, a faucet mounting hole, and a panel. Unlike the countertop, it does not need to drill on its own.

On the other hand, the undermount sink requires installing a faucet onto the countertop because of its structure and manufacturing process. Generally, we can only install it on our countertops. The hole drilled is not detachable.

Once installed in a top-mount sink, we cannot remove it anyway. Adjustments, such as reserved holes for faucet and soap dispenser, overflow control, etc., can be made in the top-mount sink depending on the customer’s demands.

Top-mount sink generally reserve holes on the panel according to customer needs, including the faucet hole and soap dispenser hole, overflow etc.

The Manufacturing Process Dissimilarity

The molding process of the granite composite sink in actual is the resin molding process, and it is commonly known that molding of resin is often accompanied by shrinkage. The amount of resin shrank during the molding process.

The final product’s quality often determines the overall dimensional accuracy and plane accuracy of the sink once its shape is formed. We can not control the shrinkage of the resin, but it shrinks with its own rule.

Therefore, the top-mount installing method is risky as the sink’s rim might shrink after being used for an extended period.

The standard rim size of a sink usually is around 30 to 35mm. The faucet hole panel has a width of 80mm. The major challenge that manufacturers face is these large flat surfaces during top-mount granite composite sinks.

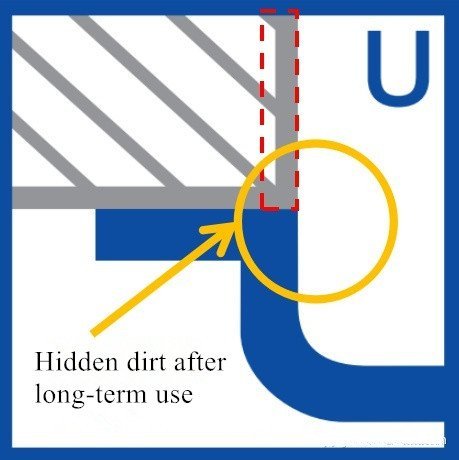

Nevertheless, the sink rim’s forefront has a high probability of being deformed as the resin shrinks. The picture below shows the deformity.

The top-mount installing method is a suitable recommendation to opt granite composite sink with a wide rim (above 30mm). Simultaneously, a sink that comes with a narrow edge (within or under 25mm) is generally suitable for the undermount installing method.

I can’t entirely agree with some manufacturers who have the sales concept of dual mount design. It is multi-purpose, no matter if it is either from the perspective of product craftsmanship or consumer use.

A granite composite sink is a high-tech industrial product, from the craftsmanship of the material molding to the product molding design. It offers its perks.

Suggestions For The Installation Method

If you have a narrow width countertop (less than 600mm), please go for the top-mount installing method.

To increase the sink area’s utilization rate, one must select the accompanying accessories, for example, the workstation sink. Also, installing a drawable styled faucet instead of a fixed faucet is a better option.

Tips for the countertop’s average width (600-650 mm)- for either of the installing methods as per the requirements. These requirements are to select a durable and elegant color countertop and choose the same color as the granite composite sink. In this way, the combination will be more harmonious.

For the vast wide (more than 650mm)-choosing the undermount installing method.

I highly recommend going for the large-size undermount sink. It is pretty spacious. You will still find space left in it after filling it with all of your kitchenware.

Conclusion

Granite composite sinks offer a lot of variety. In this article, I’ve shed light upon some of the products that exist.

I hope this article helped you in choosing the installing method.

Good luck!